In the dazzling and competitive world of makeup, packaging is far more than just a container; it’s a brand’s handshake, its visual identity, and a key part of the allure. Custom makeup packaging takes this to the next level, allowing brands to create a truly unique and memorable presentation.

Custom makeup packaging refers to primary and/or secondary packaging components (e.g., lipstick tubes, eyeshadow palettes, compacts, boxes) that are specifically designed and manufactured to a brand’s unique specifications in terms of shape, size, color, material, finish, branding elements, and functionality, rather than using standard stock options.

Customization allows a makeup brand to perfectly align its packaging with its identity, target audience, and product characteristics, creating a cohesive and impactful statement. As a premier global packaging manufacturer with ShineTop for over 20 years, we specialize in transforming brand visions into tangible, custom-designed packaging realities.

What is Custom Cosmetic Packaging?

"Custom makeup packaging" is a subset of the broader category of "custom cosmetic packaging." While makeup is a significant part, cosmetics also include skincare, haircare, and fragrance, all of which can benefit from custom packaging solutions.

Custom cosmetic packaging encompasses tailor-made packaging solutions for any beauty product (makeup, skincare, haircare, fragrance). It involves designing and producing containers, boxes, labels, and applicators to a brand’s specific requirements regarding form, material, color, branding, texture, and functional features, moving beyond standard off-the-shelf options to create a unique brand experience.

Custom cosmetic packaging is about creating a packaging solution that is as unique as the brand itself.

Key Aspects of Custom Cosmetic Packaging:

-

Unique Structural Design:

- Creating custom molds for bottles, jars, compacts, or lipstick components to achieve a proprietary shape that is instantly recognizable.

- Designing unique box structures (e.g., drawer boxes, hinged lid boxes with magnetic closures, unusual folds) that enhance the unboxing experience.

-

Specific Material Selection:

- Choosing particular grades or types of plastic (e.g., PCR content, specific resins for feel or clarity), glass (e.g., custom colors, specific weights), metal, or paperboard (e.g., specialty textured papers, specific board thickness).

- ShineTop offers a vast library of materials and can source unique options.

-

Custom Colors:

- Pantone (PMS) matching for plastics, coatings, and printing to ensure exact brand color consistency across all packaging components.

-

Bespoke Branding & Decoration:

- Printing: Custom graphics, patterns, and full-color imagery using techniques like offset printing, screen printing, or digital printing.

- Finishes: Application of specific finishes like soft-touch lamination, matte or gloss varnishes, spot UV, foil stamping (in custom colors or holographic effects), embossing, or debossing of custom patterns or logos.

- Labeling: Custom-shaped and printed labels.

-

Tailored Functionality:

- Designing custom applicators (e.g., unique mascara wands, specific dropper tips).

- Developing unique closure mechanisms.

- Incorporating features like custom-fit inserts within boxes to hold products securely and elegantly.

-

Brand Story Integration:

- Using the packaging design to tell the brand’s story, convey its values (e.g., sustainability through material choice, luxury through opulent finishes), or highlight key product ingredients/benefits.

Anna, a cosmetics manufacturer in Thailand, works with ShineTop to create custom packaging for her natural skincare and makeup lines. This includes custom-printed recycled paperboard boxes with unique botanical illustrations and PET bottles with a specific frosted finish that reflects her brand’s gentle, natural ethos.

How Does Custom Packaging Work?

The process of creating custom packaging involves a collaborative journey between the brand and the packaging supplier, from initial concept to final production.

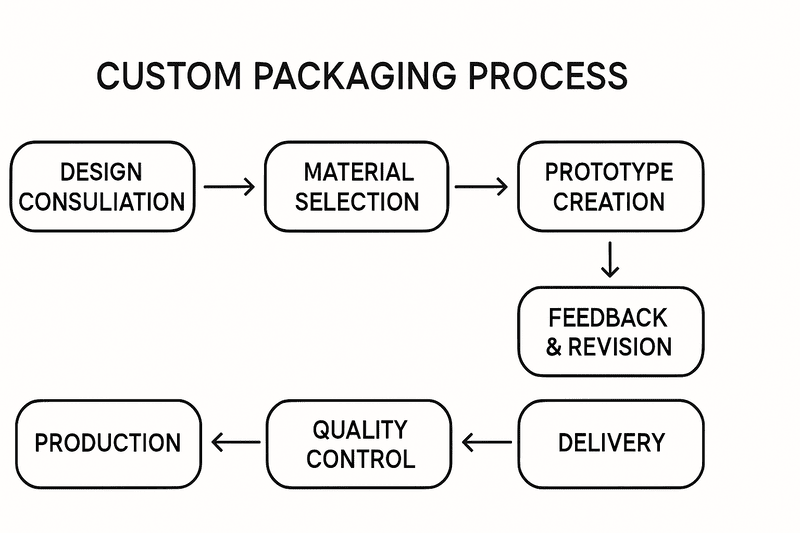

Custom packaging works through a process that typically involves: 1. Briefing & Consultation (defining needs). 2. Design & Prototyping (creating concepts, mock-ups). 3. Material & Finish Selection. 4. Quotation & Approval. 5. Pre-Production Sampling. 6. Mass Production & Quality Control. 7. Logistics & Delivery. It’s a tailored approach to meet specific brand requirements.

It’s a structured process designed to ensure the final packaging perfectly matches the brand’s vision and functional needs.

Typical Stages in the Custom Packaging Process (e.g., at ShineTop):

-

Initial Briefing & Consultation:

- Client Needs: The brand discusses its vision, target audience, product specifications, budget, quantity requirements, and desired aesthetics with the supplier.

- Supplier Input: The supplier (like ShineTop) offers expertise, suggests materials, discusses feasibility, and clarifies technical aspects.

-

Design & Conceptualization:

- Structural Design: Engineers and designers create die-lines for boxes or 3D models for containers based on the brief.

- Graphic Design: The brand (or the supplier’s design team) develops the artwork, branding elements, and print layouts.

-

Material & Finish Selection:

- Specific materials (paperboard type, plastic resin, glass quality) and finishes (lamination, foil, embossing, etc.) are chosen. Samples of materials and finishes are often reviewed.

-

Prototyping & Mock-ups:

- Digital Proofs: 2D or 3D renderings are created for review.

- Physical Prototypes (White Samples/Mock-ups): Unprinted physical samples are made to check structure, fit, and functionality. This is a crucial step.

- Printed Mock-ups: Sometimes, digitally printed mock-ups are created to give an idea of the final look.

-

Quotation & Order Confirmation:

- Based on the approved design, materials, finishes, and quantity, the supplier provides a detailed quotation.

- Once approved, the order is confirmed, and terms are agreed upon.

-

Tooling & Pre-Production Samples (PPS):

- Tooling: Custom molds (for plastic/glass containers) or cutting dies (for boxes) are created. This can involve a one-time cost.

- PPS: A final sample produced using the actual production methods, materials, and finishes. This is the "golden sample" that the brand approves before mass production begins. This is the most critical approval stage.

-

Mass Production:

- Once the PPS is approved, full-scale manufacturing begins (printing, die-cutting, gluing, assembly, component molding, decoration).

-

Quality Control (QC):

- The supplier implements QC checks throughout the production process (incoming materials, in-process, final inspection) to ensure adherence to specifications and quality standards. ShineTop has rigorous QC protocols.

-

Logistics & Delivery:

- The finished packaging is packed and shipped to the brand or their contract filler according to agreed Incoterms.

This collaborative process ensures that the custom packaging accurately reflects the brand’s vision and meets all technical and quality requirements.

What is Custom Package?

A "custom package" is simply a packaging solution that has been specifically designed and created for a particular product or brand, rather than being a standard, off-the-shelf item.

A custom package is a packaging solution (container, box, label, etc.) that is uniquely designed and manufactured to meet the specific requirements of a particular product and brand. This includes tailored dimensions, shape, materials, colors, branding, graphics, and functional features, differentiating it from generic or stock packaging options.

The essence of a custom package is its uniqueness and its perfect alignment with the product it houses and the brand it represents.

Characteristics of a Custom Package:

- Tailored Fit: Dimensions are precise to the product, ensuring a snug, protective fit and optimal presentation.

- Unique Design: Can feature proprietary shapes, structures, or opening mechanisms that are not available as stock items.

- Brand-Specific Aesthetics: Colors are often Pantone-matched to brand guidelines; graphics and logos are seamlessly integrated.

- Material Choice: Materials can be selected for specific functional properties (e.g., barrier needs, durability) or aesthetic qualities (e.g., texture, sustainability).

- Purpose-Driven Functionality: Dispensing mechanisms, closures, or inserts are designed for the specific product and user experience.

- Exclusivity: Creates a sense of uniqueness and can enhance the perceived value of the product.

Mohammed, my client from Iraq, orders exclusively custom packages for his luxury gift sets. Each element, from the drawer box structure to the custom foam inserts and the foil-stamped branding, is designed specifically for his client’s products, creating a truly bespoke presentation. This is the power of custom packaging.

What are the Different Types of Packaging for Cosmetics?

The cosmetic industry employs a vast and diverse range of packaging types to suit the myriad forms, functions, and brand aesthetics of its products. These can be broadly categorized into primary and secondary packaging.

Different types of packaging for cosmetics include primary containers like bottles (glass, plastic with various dispensers like pumps, sprayers, droppers), jars (glass, plastic), tubes (plastic, laminate, aluminum), airless systems, compacts, lipstick/lip gloss applicators, and mascara wands. Secondary packaging mainly consists of paperboard folding cartons or premium rigid boxes, along with labels and informational inserts.

This diversity allows brands to select or custom-design packaging that perfectly meets their product’s needs.

Common Categories (Primary & Secondary):

Primary Packaging (Direct Product Contact):

- Bottles: For liquids (serums, toners, foundations, lotions, perfumes). Materials: Glass, PET, HDPE, PP. Dispensers: Pumps, sprayers, droppers, caps.

- Jars: For creams, balms, masks, scrubs. Materials: Glass, PP, PET, Acrylic.

- Tubes: For creams, gels, cleansers. Materials: PE, Laminate (ABL/PBL), Aluminum.

- Airless Systems: Bottles or jars with airless pump mechanisms to protect sensitive formulas.

- Compacts: For pressed powders, eyeshadows, blushes. Often plastic, with mirrors.

- Lipstick Components: Cases/tubes with mechanisms. Plastic or metal.

- Lip Gloss Vials/Tubes: With wand applicators.

- Mascara Vials & Wands: Specialized for lash application.

- Droppers (Pipettes): For serums, oils.

- Specialized Applicators: Rollerballs, spatulas, brush tips integrated into primary packaging.

Secondary Packaging (Outer Packaging):

- Folding Cartons (Boxes): Most common; made from paperboard (SBS, CUK, recycled). Highly customizable with printing and finishes. This is a core product for ShineTop.

- Rigid Boxes (Set-Up Boxes): Premium, non-collapsible boxes for luxury items, gift sets. Made from thick greyboard with paper wraps.

- Sleeves: Paperboard bands that slide over primary packaging or simpler boxes.

- Labels: Applied to primary or secondary packaging for branding and information.

- Inserts/Leaflets: Provide additional product information or brand story.

Custom makeup packaging often involves creating unique versions of these primary components (e.g., a custom-molded lipstick case) and/or highly distinctive secondary packaging (e.g., a uniquely shaped box with special finishes). The goal is to create a cohesive and memorable packaging system.

Conclusion

Custom makeup packaging offers brands the power to create a unique and compelling physical identity for their products. By moving beyond stock options and engaging in a collaborative design and manufacturing process with a knowledgeable supplier like ShineTop, brands can develop tailor-made bottles, tubes, compacts, and boxes that perfectly protect their formulations, resonate with their target audience, and powerfully communicate their brand story, ultimately enhancing perceived value and driving consumer desire.