Want to use the best lavender oil but feel lost in the terminology? The extraction method directly impacts the oil’s quality, scent, and cost, and choosing wrong can affect your product.

The three main ways to extract lavender oil are steam distillation, solvent extraction, and CO2 extraction. Steam distillation is the most common method for producing essential oil. Solvent extraction creates a thicker, more fragrant "absolute," while CO2 extraction yields an extremely pure, high-quality extract.

Knowing the difference between these methods is crucial for anyone creating cosmetics or aromatherapy products. The process used to get the oil out of the plant determines its chemical makeup, its aroma profile, and its best application. As a packaging supplier, I’ve seen how the quality of an oil dictates the entire product’s value. Let’s look at each method so you can understand what you’re really buying.

How does steam distillation for lavender oil work?

You see "steam distilled" on almost every bottle of essential oil. But what does this common term actually mean for the lavender oil inside? Let’s uncover the process.

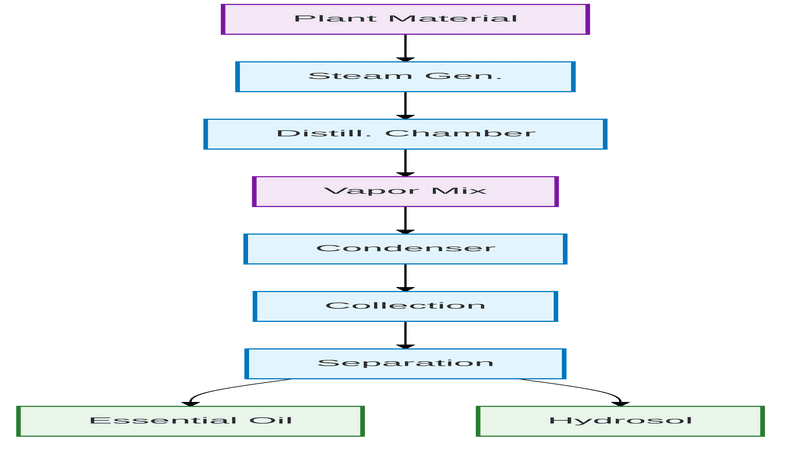

Steam distillation is the most popular method. It involves passing hot steam through freshly harvested lavender flowers. The steam causes the plant’s microscopic oil sacs to burst, releasing the aromatic molecules. This vapor mixture is then cooled, separating the pure essential oil from the water.

This method is the workhorse of the essential oil industry. It’s a balance of efficiency and quality. Most of my clients, like Anna who runs a cosmetics brand in Thailand, rely on steam-distilled lavender oil. It provides the therapeutic benefits and classic scent her customers love, at a price point that works for her products. The process itself is a fascinating mix of agriculture and chemistry. The lavender is harvested and often left to wilt for a day to reduce the water content. Then it’s loaded into a large container called a still. Steam is injected, and as it rises through the flowers, it carries the precious oil with it. The resulting vapor is channeled into a condenser, which cools it back into liquid form. Because oil and water don’t mix, the essential oil floats on top of the water, where it can be easily collected.

| Pros of Steam Distillation | Cons of Steam Distillation |

|---|---|

| Produces a very pure essential oil | High heat can damage delicate compounds |

| Cost-effective and efficient | Less complex aroma than other methods |

| No chemical solvents are used | Yield can be lower for some plants |

| The industry standard for quality | Requires significant plant material |

Can you extract lavender oil using solvents?

You might have seen products called "lavender absolute" and wondered how it’s different. This name points to a completely different extraction method that uses chemical solvents instead of steam.

Yes, you can. Solvent extraction uses a chemical like hexane to wash the aromatic compounds from the lavender flowers. This creates a waxy substance called a "concrete." The concrete is then mixed with alcohol to filter out the waxes, leaving a highly fragrant liquid called an "absolute."

This method is not for creating a therapeutic essential oil. It’s all about capturing the truest, deepest scent of the flower. The process is much gentler than steam distillation because it doesn’t use high heat. This means it captures larger, heavier aromatic molecules that are lost in the steam process. The result is an aroma that is richer, rounder, and much closer to the smell of fresh lavender. Because of its complex scent profile and the potential for trace amounts of solvent residue, absolutes are almost exclusively used in high-end, natural perfumery. They are not typically recommended for skincare or aromatherapy where purity is the top concern.

Concrete vs. Absolute

The process involves two distinct products:

| Product | Description | Main Use |

|---|---|---|

| Concrete | A semi-solid, waxy substance containing aromatic compounds and plant waxes. | A stable intermediate for making absolutes. |

| Absolute | A thick, highly aromatic liquid created by washing the concrete with alcohol. | High-end perfumery and fragrance. |

What is CO2 extraction for lavender oil?

You’re looking for the absolute purest, most complete lavender extract possible. You want an oil that captures the plant’s essence without heat or chemical solvents. This is where modern technology comes in.

CO2 extraction is a modern, advanced method that uses pressurized carbon dioxide (CO2) as a solvent. In a special chamber, the CO2 is put under pressure until it reaches a "supercritical" state, where it acts like both a liquid and a gas, allowing it to dissolve the oil from the lavender.

This method is the gold standard for purity. Because it uses no heat, it preserves all the delicate, heat-sensitive compounds that are damaged during steam distillation. Once the extraction is complete, the pressure is released, and the CO2 simply turns back into a gas and evaporates completely, leaving zero residue. The resulting CO2 extract is the most complete representation of the original plant, with a scent and chemical profile that is incredibly rich and nuanced. The downside is the cost. The equipment is extremely expensive, which makes CO2 extracts the priciest option on the market. I recommend this for clients creating ultra-premium, therapeutic-grade products where performance and purity are the absolute top priorities. An oil this precious deserves packaging to match, like our protective airless pump bottles that prevent any oxidation.

Is cold-pressing used for lavender oil?

You know that cold-pressing is a great way to get oil from lemons and oranges. It’s natural to wonder if this simple mechanical method can also be used for lavender flowers.

No, cold-pressing is not used for lavender. This method is only effective for citrus fruits. It works by mechanically squeezing the rinds to rupture the oil sacs. Lavender flowers store their oil in delicate glands that cannot be broken open by pressure alone.

I’ve had clients ask me for "cold-pressed lavender oil" because they associate the term with high quality. It’s a common point of confusion. I always take the time to explain why it’s not possible. The anatomy of a lemon peel is very different from a lavender flower. The peel is full of tiny sacs bursting with oil, and a good squeeze is all it takes to release it. Lavender’s essential oil is held in tiny, fragile structures called trichomes on the surface of the flower. To get the oil out, you need something that can penetrate and open these structures, which is what steam or a solvent does. Trying to press lavender flowers would just give you crushed flowers with very little, if any, oil. Understanding these botanical details is key to sourcing the right ingredients for your products.

Conclusion

The way lavender oil is extracted defines its final quality. Steam distillation is the standard for pure essential oil, solvent extraction is for rich perfumes, and CO2 extraction offers ultimate purity.