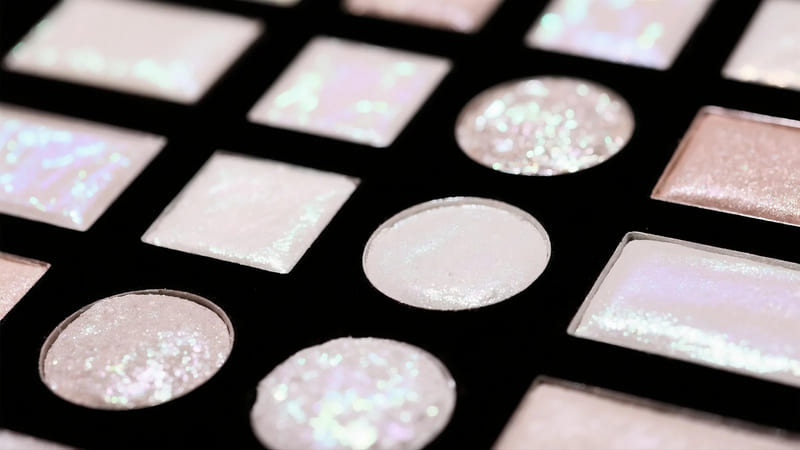

Ever admired cosmetic packaging that shimmers with an iridescent glow, catching the light in a captivating way? That magical effect is often thanks to pearlescent pigments, adding a touch of luxury and allure.

Pearlescent pigments are used in cosmetic packaging by incorporating them into plastics (masterbatch), coatings, printing inks, or hot stamping foils applied to materials like paperboard, plastic, or glass. This creates a shimmering, lustrous, or iridescent effect that enhances visual appeal and perceived value.

The use of pearlescent pigments is a sophisticated way to make cosmetic packaging stand out. At ShineTop, with our extensive post-processing and surface treatment facilities, we’ve helped many brands incorporate these beautiful effects to elevate their packaging. Let’s explore how these shimmering wonders work their magic.

What are the Uses of Pearlescent Pigments?

Pearlescent pigments aren’t just for makeup formulas themselves; their unique optical properties make them highly sought after for a wide range of applications, including adding glamour to packaging.

Pearlescent pigments are used to create effects of luster, shimmer, sparkle, or iridescence on various surfaces. In addition to cosmetics themselves, their uses include automotive paints, plastics, printing inks (for packaging, publications), coatings, textiles, and arts and crafts.

The versatility of pearlescent pigments stems from their ability to mimic the natural luster of pearls and nacre (mother-of-pearl).

Common Applications:

-

Cosmetics (The Product Itself):

- Makeup: Eyeshadows, highlighters, blushes, lipsticks, nail polishes, body shimmers. They provide sparkle, glow, and color-shifting effects.

- Personal Care: Shimmering lotions, shower gels, and hair products.

-

Automotive Paints:

- Create metallic or pearlescent finishes on cars, giving them depth and color travel (changing color depending on the viewing angle).

-

Plastics:

- Incorporated into plastic resins (as a masterbatch) to give products like electronics casings, toys, and cosmetic containers a pearlescent appearance.

-

Printing Inks & Coatings:

- Used in inks for offset, flexographic, gravure, and screen printing to add shimmer to packaging (boxes, labels), magazines, greeting cards, and wallpaper.

- Applied as coatings on various substrates for a lustrous finish.

-

Textiles & Leather:

- Used to create shimmering effects on fabrics and leather goods.

-

Arts & Crafts:

- Available as powders or in paints for artists and crafters to add pearlescent effects to their creations.

-

Food & Pharmaceuticals (Specific Grades):

- Edible grades of pearlescent pigments (often mica-based with titanium dioxide and/or iron oxides) are used to add shimmer to candies, cake decorations, and pill coatings.

The underlying principle is always to enhance visual appeal by manipulating light. In cosmetic packaging, this translates to a more luxurious and eye-catching presentation.

How Do You Use Pearlescent Pigment Powder?

For those looking to apply pearlescent effects, especially in smaller-scale operations or DIY projects related to packaging mock-ups or crafts, understanding how to use the powder form is key.

Pearlescent pigment powder is typically used by dispersing it into a clear or translucent medium or binder, such as varnish, lacquer, resin, plastic, ink base, or even a clear glue. The mixture is then applied to the desired surface by spraying, brushing, printing, or incorporating it into a material during its manufacturing process.

Using pearlescent pigment powder effectively requires proper dispersion in a suitable carrier. The method of application depends on the substrate and the desired effect.

General Steps for Using Pearlescent Pigment Powder in Coatings/Inks:

-

Choose the Right Pigment:

- Select the desired color, particle size (finer particles give a smoother, satiny luster; coarser particles give more sparkle), and type of pearlescent pigment (e.g., mica-based, synthetic mica, bismuth oxychloride).

-

Select a Compatible Binder/Medium:

- This needs to be clear or translucent to allow the pearlescent effect to show through. Examples include clear acrylic varnish, polyurethane lacquer, epoxy resin, screen printing ink base, or a plastic masterbatch carrier.

- The binder must be compatible with the substrate you’re applying it to (e.g., paper, plastic, metal).

-

Determine the Loading Level (Pigment-to-Binder Ratio):

- This varies depending on the desired intensity of the effect. Typical loading levels might range from 1% to 25% by weight, but it’s best to start with small test batches. Too little pigment results in a weak effect; too much can sometimes dull the effect or cause application issues.

-

Dispersion:

- Gradually add the pearlescent pigment powder to the binder while stirring gently but thoroughly. Avoid overly aggressive mixing that could break delicate mica platelets, though most are quite robust.

- Ensure there are no clumps and the pigment is evenly distributed. Some applications might require specific mixing equipment for optimal dispersion.

-

Application:

- Spraying: For even coats on 3D objects or flat surfaces.

- Brushing: For smaller areas or artistic effects.

- Printing: In screen printing, flexography, or gravure, the pigmented ink is transferred to the substrate.

- Incorporation into Plastics: The pigment (often as a masterbatch) is mixed with the plastic resin before molding.

-

Curing/Drying:

- Allow the applied coating or ink to dry or cure according to the binder manufacturer’s instructions.

For Cosmetic Packaging Manufacturing (like at ShineTop):

- In Plastics: Pearlescent masterbatch is added to the plastic resin (e.g., PP, PET, ABS) during injection molding or extrusion to create pearlescent bottles, caps, or jars.

- In Coatings: Pearlescent lacquers are sprayed onto components.

- In Printing Inks: Pearlescent inks are used for offset or screen printing directly onto paperboard boxes or labels.

- Hot Stamping Foils: Pearlescent effects can also be achieved using specialized hot stamping foils.

Anna, a cosmetics manufacturer in Thailand, wanted a subtle pearlescent sheen on the caps of one of her skincare lines. We achieved this by using a custom pearlescent masterbatch in the PP material for the caps during injection molding.

What are Pigments Used For in Cosmetics?

Pigments are the very essence of color in cosmetics, transforming creams and powders into a vibrant palette for self-expression and enhancement.

In cosmetics, pigments are used to impart color, opacity, and special effects (like shimmer or matte finishes) to products such as foundations, eyeshadows, lipsticks, blushes, nail polishes, and eyeliners. They can be organic, inorganic, or effect pigments (like pearlescent).

Pigments are the substances that give cosmetic products their hue and visual characteristics. They are insoluble colorants that are dispersed in the cosmetic formulation.

Main Roles of Pigments in Cosmetic Formulations:

-

Imparting Color:

- This is their primary function. They provide the reds, blues, yellows, blacks, whites, and all other shades seen in makeup.

- Examples: Iron oxides (browns, reds, yellows, black), titanium dioxide (white), ultramarines (blue, pink), chromium oxides (greens).

-

Providing Coverage/Opacity:

- Pigments like titanium dioxide and zinc oxide are used in foundations and concealers to cover imperfections and even out skin tone.

-

Creating Special Effects:

- Pearlescent Pigments (Effect Pigments): Provide shimmer, luster, and iridescence.

- Matte Pigments: Ingredients like talc, kaolin, or silica can be used alongside color pigments to create a matte finish by scattering light.

- Glitter: Larger particles that provide intense sparkle (though sometimes classified separately from pigments).

-

UV Protection (Specific Pigments):

- Micronized titanium dioxide and zinc oxide also function as physical UV filters in sunscreens and foundations.

Types of Pigments Used in Cosmetics:

- Inorganic Pigments:

- Mineral-derived. Generally very stable to light and heat.

- Examples: Iron Oxides, Titanium Dioxide, Zinc Oxide, Ultramarines, Chromium Oxides, Manganese Violet.

- Organic Pigments:

- Carbon-based molecules. Can offer very bright, intense colors.

- Subdivided into "lakes" (dyes precipitated onto an inert binder) and "toners."

- Examples: D&C Red No. 7 Calcium Lake, FD&C Yellow No. 5 Aluminum Lake.

- Regulation is strict; only approved colorants can be used.

- Effect Pigments:

- These don’t primarily provide color but create optical effects.

- Pearlescent Pigments: Mica coated with metal oxides (like titanium dioxide or iron oxide).

- Bismuth Oxychloride: Provides a silvery pearl effect.

The choice and combination of pigments are crucial for achieving the desired shade, finish, and performance of a cosmetic product. This is distinct from their use on packaging, but the aesthetic goals are often similar – to create visual appeal.

How Does Pearlescent Work?

The captivating shimmer of a pearl or the iridescent sheen on a butterfly’s wing is a natural marvel. Pearlescent pigments in packaging and cosmetics aim to replicate this beautiful optical phenomenon.

Pearlescent effects work through the principle of light interference and reflection. Pearlescent pigments consist of thin, flat platelets (often mica coated with metal oxides like titanium dioxide). Light striking these platelets is partially reflected from the surface and partially transmitted through, reflecting off lower layers. The interference between these light waves creates the characteristic shimmering, lustrous, or iridescent colors.

The magic of pearlescence lies in how these tiny platelets interact with light. It’s not about a single color, but a play of light.

The Science Behind the Shimmer:

-

Platelet Structure:

- Most common pearlescent pigments are made of a core substrate, typically natural mica (a transparent mineral) or synthetic mica (fluorphlogopite), or sometimes silica or alumina flakes.

- This core platelet is coated with one or more thin layers of metal oxides, most commonly titanium dioxide (TiO₂) and/or iron oxides (Fe₂O₃).

-

Light Interaction (Reflection & Refraction):

- When light hits these coated platelets, some of it is reflected from the top surface of the metal oxide coating.

- Some light passes through the transparent metal oxide layer and the mica core, then reflects off the bottom surface of the metal oxide coating or subsequent layers.

-

Interference:

- The light waves reflected from these different surfaces travel slightly different distances. When these waves recombine, they interfere with each other.

- Constructive Interference: If the waves are in phase, certain wavelengths (colors) are intensified, leading to the observed color.

- Destructive Interference: If the waves are out of phase, certain wavelengths are canceled out.

-

Color Generation:

- The perceived color depends on the thickness of the metal oxide coating.

- Thinner TiO₂ layers produce silvery or bluish interference colors.

- As the TiO₂ layer thickness increases, the interference color shifts through gold, red, violet, blue, and green.

- If an absorbent material like iron oxide is used in the coating, it can create "absorption" colors (like bronze or copper) in addition to interference effects.

- The perceived color depends on the thickness of the metal oxide coating.

-

Luster and Sparkle:

- The smooth, parallel alignment of these platelets in a medium (like an ink, coating, or plastic) is crucial for achieving a strong pearlescent luster.

- The size of the platelets also influences the effect:

- Small particles (e.g., 5-25 microns): Create a smooth, satiny, pearly luster with good hiding power.

- Medium particles (e.g., 10-60 microns): Provide a silky shimmer.

- Large particles (e.g., 20-100+ microns): Produce a more sparkly, glittering effect with higher transparency.

This interplay of reflection, refraction, and interference is what gives pearlescent packaging its dynamic, eye-catching quality, making it appear to shift in color and intensity as the viewing angle changes. At ShineTop, our ability to precisely control coating applications and masterbatch incorporation allows us to achieve consistent and beautiful pearlescent effects for our clients’ cosmetic packaging.

Conclusion

Pearlescent pigments are a versatile tool for enhancing cosmetic packaging, creating captivating shimmers and lustrous finishes by manipulating light. Used in plastics, inks, and coatings, they elevate the visual appeal and perceived value of products, making them stand out on the shelf. Understanding how these pigments work allows for their strategic application in creating truly attractive and memorable packaging.