Essential oils, with their potent aromas and therapeutic properties, are precious commodities. Their packaging, especially the outer box, needs to reflect this quality, protect the delicate bottles, and convey the brand’s essence, whether it’s natural purity, luxurious indulgence, or clinical efficacy.

To make the best essential oil packaging boxes, use high-quality, sturdy paperboard (SBS, Kraft, or recycled content), design for a snug and protective fit for the glass bottle(s), incorporate branding that reflects the oil’s nature (e.g., botanical, minimalist, luxury), utilize clear and compliant labeling, and consider premium finishes like embossing or foil stamping for an enhanced perceived value.

Crafting the "best" box for essential oils is about balancing protection, aesthetics, branding, and often, sustainability. As a packaging manufacturer with ShineTop for over two decades, we’ve helped numerous brands create packaging that elevates their essential oil products. Let’s explore how to achieve this.

What is the Best Packaging for Essential Oils?

Essential oils are sensitive to light and air, and their concentrated nature means their primary container needs to be carefully chosen. The secondary packaging (the box) then complements and protects this.

The best primary packaging for essential oils is almost always dark-colored glass bottles (amber, cobalt blue, sometimes dark green or violet Miron glass) to protect against UV light degradation. These bottles should have well-fitting caps, often with orifice reducers or droppers for controlled dispensing. The best secondary packaging (box) is sturdy, provides further light protection, offers branding space, and cushions the glass bottle.

The packaging system for essential oils must prioritize preservation and safety.

Ideal Packaging Components for Essential Oils:

-

Primary Container (The Bottle):

- Material: Glass is paramount due to its inertness (doesn’t react with the oils) and impermeability.

- Color: Dark glass (amber is most common, followed by cobalt blue) is essential to filter out UV light, which can degrade essential oils and reduce their potency and shelf life. Violet Miron glass is a premium option known for its unique light-filtering properties.

- Closure:

- Tamper-Evident Caps: Provide security.

- Child-Resistant Caps (CRCs): Important for safety, especially as essential oils are concentrated.

- Orifice Reducers: Plastic inserts that allow for dispensing by the drop.

- Glass Dropper Pipettes: For easy and precise application, common for diluted oils or blends.

-

Secondary Packaging (The Box):

- Material: Sturdy paperboard (e.g., SBS for a clean print surface, Kraft for a natural look, recycled board for sustainability). For luxury sets or larger bottles, rigid (set-up) boxes offer superior protection and a premium feel.

- Function:

- Protection: Cushions the glass bottle against breakage during shipping and handling.

- Light Blocking: Provides an additional barrier against light.

- Branding & Information: Offers ample space for brand identity, oil name, botanical name, ingredients (if a blend), usage instructions, safety warnings, volume, batch number, and origin.

- Inserts (Optional but Recommended for Boxes): Corrugated cardboard or custom paperboard inserts within the box can hold the bottle snugly, preventing movement and adding extra cushioning. Molded pulp is an eco-friendly insert option.

-

Labels:

- On both the bottle and the box. Must be oil-resistant to prevent smudging or peeling.

- Clear, legible, and compliant with local regulations.

The "best" packaging ensures the essential oil reaches the consumer in its purest, most effective state, beautifully presented and safely contained. ShineTop often produces custom-printed folding cartons and rigid boxes specifically designed to hold these precious glass bottles securely.

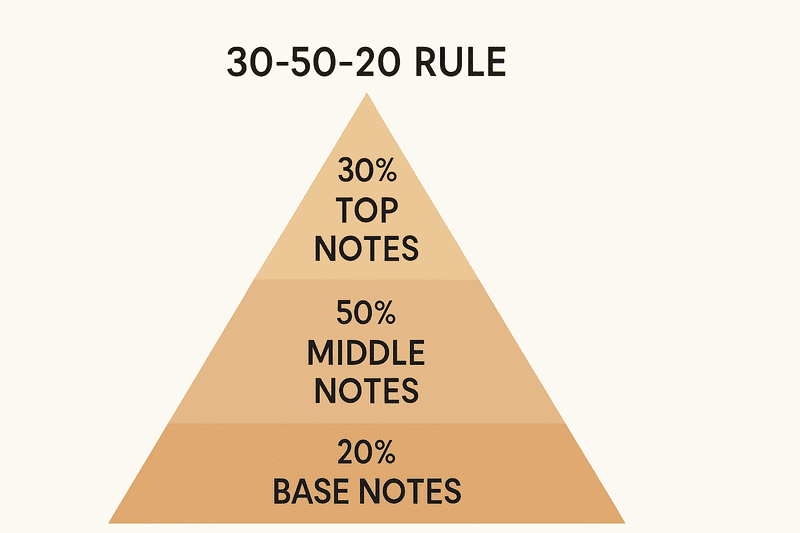

What is the 30 50 20 Rule for Essential Oils?

This rule isn’t about packaging directly, but rather about a common guideline for creating balanced essential oil blends for aromatherapy or perfumery. Understanding it can sometimes influence how blends are marketed and, by extension, how their packaging might reflect their composition.

The 30-50-20 rule for essential oils is a blending guideline suggesting a ratio for combining top, middle, and base notes to create a harmonious and well-rounded aroma: approximately 30% top notes (light, volatile, first impression), 50% middle notes (heart of the blend, balancing), and 20% base notes (deep, grounding, longest-lasting).

This rule helps create blends that evolve pleasantly over time.

- Top Notes (30%):

- Light, fresh, uplifting, and volatile. They are the first scents you detect but evaporate quickly.

- Examples: Citrus oils (lemon, bergamot, grapefruit), peppermint, eucalyptus.

- Middle Notes (50% – The "Heart"):

- Full-bodied, well-rounded, and form the core of the blend. They emerge after the top notes fade and help to balance the aroma.

- Examples: Floral oils (lavender, geranium, rose, jasmine), spice oils (clove, cinnamon – use sparingly), herbal oils (rosemary, chamomile).

- Base Notes (20% – The "Fixatives"):

- Deep, rich, heavy, and grounding. They evaporate slowly, providing depth and longevity to the blend. They also help to "fix" the lighter notes.

- Examples: Woody oils (sandalwood, cedarwood, vetiver), resinous oils (frankincense, myrrh), vanilla.

Relevance to Packaging Design (Indirect):

While not a packaging rule, if a brand creates blends based on this principle, the packaging design might subtly reflect the blend’s character:

- A blend rich in bright top notes might have lighter, more vibrant packaging.

- A blend with prominent, grounding base notes might use darker, earthier tones or more substantial-feeling packaging.

- The description on the box might allude to the different notes within the blend.

What Plastic is Best for Essential Oils?

This is a critical question, as essential oils are highly concentrated and can degrade or react with many plastics. The general rule is to avoid plastic for undiluted essential oils.

For undiluted essential oils, NO plastic is generally considered "best" or safe for long-term storage; glass is the standard. However, for diluted essential oil preparations (e.g., in a carrier oil for rollerballs, or in lotions/creams), high-quality, chemically resistant plastics like HDPE (High-Density Polyethylene) or PET (Polyethylene Terephthalate) might be acceptable for short-term use or specific applications, but thorough compatibility testing is essential. PP (Polypropylene) is often used for orifice reducers and caps.

Pure, undiluted essential oils can be powerful solvents and can break down many types of plastic over time, leading to:

- Leaching of plastic chemicals into the oil, contaminating it.

- Degradation of the oil’s therapeutic properties and aroma.

- Deterioration of the plastic container itself (warping, cracking, clouding).

Plastic Considerations for Essential Oil Related Products:

-

HDPE (High-Density Polyethylene – #2):

- Offers better chemical resistance than many other plastics.

- Sometimes used for bottles containing products with a low percentage of essential oils (e.g., some natural cleaning solutions, massage oils where EOs are heavily diluted).

- Still, long-term storage of anything with significant EO content is questionable.

-

PET / PETG (Polyethylene Terephthalate – #1):

- Good clarity and reasonable chemical resistance.

- May be used for products with very low, well-diluted essential oil content, like some room sprays or body mists.

- Amber PET can offer some UV protection.

-

PP (Polypropylene – #5):

- Commonly used for caps, orifice reducers, and sometimes rollerball fitments for diluted essential oil blends. PP has good resistance to many chemicals.

Key Rule: If the product is PURE, UNDILUTED essential oil, or a very high concentration blend, always use glass.

For brands creating products containing essential oils (like Anna’s natural cosmetics in Thailand, which use EOs for scent and benefits), the choice of plastic for the primary container (if not glass) requires rigorous compatibility testing with the final formulation. At ShineTop, if a client is packaging a formula with essential oils in plastic, we always recommend extensive testing.

How to Package Essential Oils for Shipping?

Shipping essential oils, especially in glass bottles, requires careful packaging to prevent breakage, leakage, and to comply with any shipping regulations (as some EOs can be considered flammable or hazardous materials in larger quantities).

To package essential oils for shipping: 1. Ensure bottles have tight, leak-proof caps. 2. Individually wrap each glass bottle in cushioning material (e.g., bubble wrap). 3. Place wrapped bottles in a sturdy secondary box, often with dividers or custom inserts to prevent movement. 4. Use a strong outer shipping carton with ample void fill (packing peanuts, air pillows) on all sides. 5. Label correctly, including "Fragile" and any required hazmat warnings if applicable.

Safe shipping is crucial to ensure your precious oils arrive intact.

Steps for Secure Shipping:

-

Primary Container Check:

- Ensure caps are tightly secured. If using dropper tops, ensure they are also tight.

- Consider adding a small piece of parafilm or tape around the cap/bottle neck junction for extra security against leaks, especially for air freight.

-

Individual Bottle Protection:

- Wrap each glass bottle generously in bubble wrap or a foam sleeve.

- Alternatively, use custom-molded pulp inserts or die-cut foam inserts within their individual retail boxes.

-

Retail Box (Secondary Packaging):

- If the essential oil has its own retail box (as discussed for "best essential oil boxes"), this provides an additional layer of protection. Ensure the bottle fits snugly inside, perhaps with a paperboard insert.

-

Inner Packing within Shipping Carton:

- If shipping multiple bottles/boxes, use sturdy cardboard dividers to separate them and prevent them from colliding.

- Place them in a smaller, sturdy inner box if shipping many.

-

Outer Shipping Carton:

- Use a new, high-quality corrugated cardboard box. Double-walled boxes are recommended for heavier or international shipments.

- The box should be large enough to accommodate the oils plus at least 2 inches of cushioning on all sides.

-

Cushioning & Void Fill:

- Line the bottom of the shipping carton with cushioning material (bubble wrap, packing peanuts, foam).

- Place the individually wrapped bottles or their retail boxes inside.

- Fill ALL empty spaces with void fill material to prevent any movement. The contents should not shift when you gently shake the box.

- Add a layer of cushioning on top before sealing.

-

Sealing the Carton:

- Use strong packing tape (not masking or cellophane tape) to securely seal all seams and flaps (H-tape method).

-

Labeling:

- Clear shipping labels with sender and recipient addresses.

- Mark "FRAGILE" and "HANDLE WITH CARE" clearly on multiple sides. "THIS WAY UP" arrows are also good.

- Hazardous Materials (Hazmat/Dangerous Goods): Some essential oils, due to their flashpoints, may be classified as flammable liquids (Class 3 Dangerous Goods) by shipping carriers (IATA for air, IMDG for sea, DOT for ground). This depends on the specific oil, quantity, and mode of transport. If shipping regulated quantities, you MUST comply with all specific packaging, labeling (hazmat diamonds), and documentation requirements. Consult your carrier or a dangerous goods specialist.

When ShineTop ships finished packaging (like empty glass essential oil bottles or their boxes) to clients, we use robust export-grade cartons and careful internal packing to ensure they arrive undamaged. The same diligence is needed when shipping the filled products.

Conclusion

Creating the best essential oil packaging boxes involves using quality paperboard, designing for both protection and brand aesthetics, and ensuring clear, compliant labeling. While glass is non-negotiable for primary storage of pure oils, understanding blending principles and safe shipping practices completes the picture for successfully bringing these aromatic treasures to market. Careful attention to detail at every stage, from box design to final shipment, is key.