The perfume bottle is a vessel of artistry and function, designed not only to be beautiful but also to be the perfect guardian for the precious and volatile fragrance within. The choice of material is paramount to achieving both these goals.

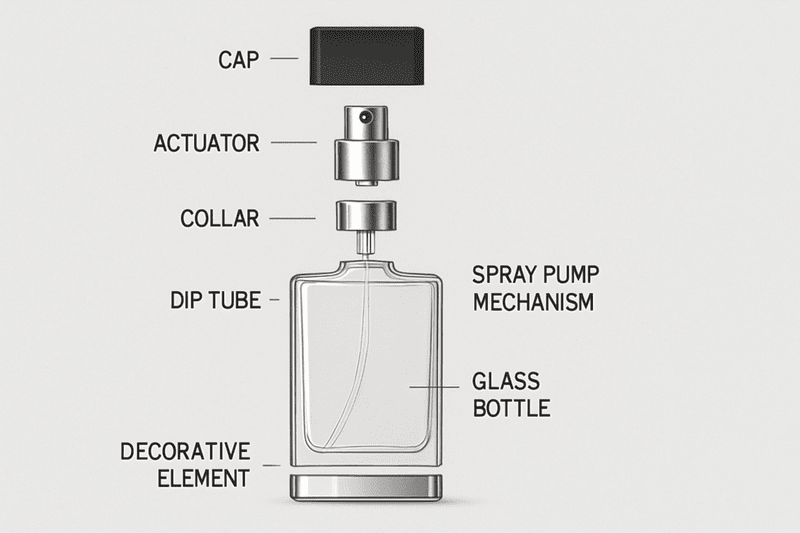

Modern perfume bottles are predominantly made of glass, chosen for its chemical inertness and premium aesthetic. Key components include the glass bottle itself, a plastic and metal atomizer pump, a plastic dip tube, a decorative actuator (nozzle), and a cap made from a variety of materials like plastic (Surlyn, ABS), metal (Zamac, aluminum), wood, or resin.

The combination of these materials creates a functional, safe, and often luxurious object. As a global packaging manufacturer with ShineTop, we specialize in producing these high-quality components, understanding how each material contributes to the final product. Let’s explore the materials in detail.

What is a Perfume Bottle Made Of?

A modern perfume bottle is an assembly of several distinct parts, each often made from a different material selected for its specific functional or aesthetic properties.

A typical perfume bottle is an assembly: the main body is almost always glass. The spray mechanism (atomizer) is a complex mix of plastic (like PP) for the housing and a small metal spring. The dip tube is plastic (PE or PP). The actuator (nozzle) can be plastic or metal. The cap can be plastic, metal (often Zamac or aluminum), wood, or other decorative materials.

Let’s break down the material of each part:

-

The Bottle (Flacon):

- Glass: The standard choice. It’s chemically inert, so it doesn’t react with the alcohol or fragrance oils, preserving the scent’s integrity.

- Crystal: Used for very high-end, luxury, or limited-edition bottles. It’s heavier and more brilliant than standard glass.

-

The Atomizer (Pump Mechanism):

- This is a multi-material component.

- Housing & Piston: Usually made from chemically resistant plastics like Polypropylene (PP).

- Spring: A tiny spring, almost always made of stainless steel, provides the pump action. This metal spring is one reason why recycling the entire pump assembly is difficult.

- Gaskets: Small seals, often made from specific types of rubber or plastic (like LDPE), ensure an airtight seal.

-

The Dip Tube:

- The thin straw inside the bottle is made from a flexible, chemically resistant plastic, typically Polyethylene (PE) or Polypropylene (PP).

-

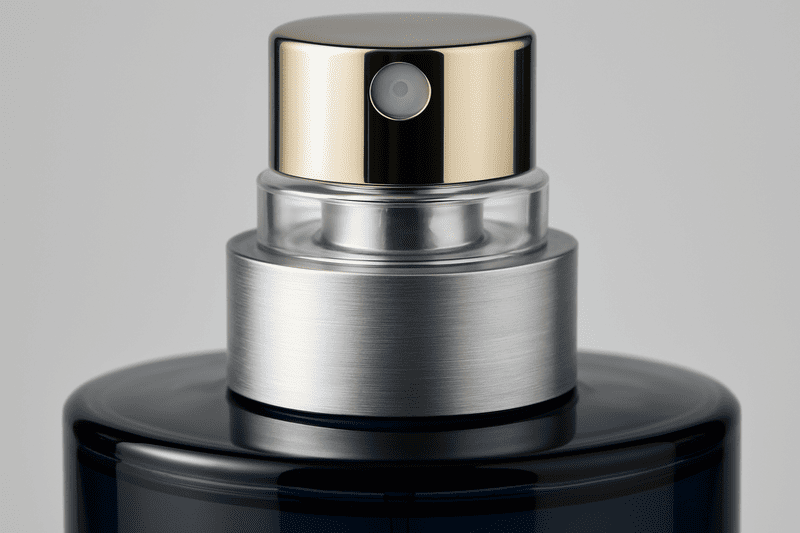

The Actuator (Nozzle/Button):

- The part you press. Can be made from various materials for aesthetic and tactile reasons.

- Plastic (ABS, PP): Can be molded into many shapes and colored or metallized.

- Metal (Aluminum, Zamac): Provides a cooler touch and a more premium feel.

-

The Cap:

- This part has the most material variety, as its primary role is aesthetic and protective.

- Plastic (Surlyn, ABS, PP): Surlyn is popular for its clarity and weight. ABS is versatile for coloring and metallizing.

- Zamac (Zinc Alloy): Very popular for luxury perfumes due to its heavy weight, cool metallic feel, and ability to be molded into intricate shapes and plated with finishes like gold or chrome. My client Mohammed from Iraq often specifies custom Zamac caps for his luxury fragrance sets.

- Aluminum: Lightweight, sleek, modern feel.

- Wood/Bamboo: For a natural, artisanal, or eco-conscious look.

- Resin: Can be used to create unique, often colorful or marbled designs.

What Type of Glass is Used for Perfume Bottles?

Not all glass is the same. The type of glass used for perfume bottles is chosen for its clarity, formability, and chemical resistance, though it differs from the glass used for pharmaceuticals.

Perfume bottles are typically made from high-quality soda-lime glass, specifically a cosmetic-grade variant. This type of glass offers excellent clarity, is highly formable into complex shapes, and has sufficient chemical resistance for alcohol-based fragrances. It is classified as Type III glass in the pharmaceutical glass typology.

While laboratory or pharmaceutical glass might be borosilicate, cosmetic glass has different priorities.

Glass Types Explained:

-

Soda-Lime Glass (Type III Glass):

- Composition: Made primarily from silica (sand), soda (sodium carbonate), and lime (calcium oxide).

- Properties: This is the most common type of glass produced globally. It has excellent workability, meaning it can be easily molded, blown, and pressed into the intricate and beautiful shapes required for perfume bottles. It offers good clarity and is relatively inexpensive to produce compared to other types.

- Suitability for Perfume: Its chemical resistance is sufficient to handle the alcohol and oil mixtures in perfumes without reacting or leaching. It provides the perfect balance of aesthetic potential, chemical stability for its purpose, and manufacturing viability.

- ShineTop’s Production: The vast majority of the cosmetic glass bottles and jars we produce are made from high-grade soda-lime glass.

-

Borosilicate Glass (Type I Glass):

- Composition: Contains boron trioxide, which gives it very high chemical resistance and, crucially, very low thermal expansion.

- Properties: Highly resistant to chemical corrosion and thermal shock (sudden temperature changes). This is the type of glass used for laboratory equipment (Pyrex) and for parenteral (injectable) pharmaceutical vials.

- Use in Perfume: Rarely used for commercial perfume bottles because it’s more expensive to produce and its superior thermal properties are not necessary for this application. The aesthetic focus and formability of soda-lime glass are more important for perfumes.

-

Crystal (Lead Glass):

- Composition: Glass that contains lead oxide or other metal oxides (like barium or potassium) to increase its refractive index.

- Properties: Exceptional brilliance, clarity, and weight. It sparkles more than standard glass.

- Use in Perfume: Reserved for ultra-luxury, limited edition, or collector’s bottles (e.g., by Baccarat, Lalique).

So, when you hold a standard perfume bottle, you are almost certainly holding cosmetic-grade soda-lime glass.

Why are Perfume Bottles So Thick?

Many perfume bottles, especially those from luxury brands, have a noticeable heft and thickness, particularly at the base. This is a deliberate design choice that serves both functional and psychological purposes.

Perfume bottles are often made with thick glass, especially at the base, for several reasons: 1. To convey a sense of luxury, quality, and value through added weight and substance. 2. To provide stability and prevent the bottle from tipping over easily. 3. To enhance the visual presentation of the fragrance, with the thick base refracting light beautifully. 4. To add durability and strength.

The thickness is a key part of the sensory experience and brand positioning.

Reasons for Thick Glass:

-

Perception of Luxury & Value:

- Weight = Quality: In consumer psychology, there is a strong association between weight and quality. A heavy, substantial bottle feels more expensive, luxurious, and important than a lightweight, flimsy one.

- This tactile feedback reinforces the premium price point of the fragrance.

-

Stability:

- A thick, heavy base lowers the bottle’s center of gravity, making it much more stable and less likely to be knocked over on a vanity or shelf. This is especially important for taller, more slender bottle designs.

-

Aesthetic Enhancement:

- A thick glass base, often called a "puck," acts like a lens. It can capture and refract light in a beautiful way, enhancing the color of the perfume liquid and making the entire bottle sparkle. It adds visual depth and presence.

-

Durability:

- While all glass is breakable, a thicker wall and base provide greater strength and resistance to chipping or cracking from minor impacts compared to thin glass.

-

Design Element:

- The shape and depth of the thick base can be a key part of the bottle’s unique design silhouette.

At ShineTop, when we work with luxury brands like those Anna from Thailand aspires to emulate, we often recommend designs with a heavier glass base to achieve that essential premium feel.

What Were Old Perfume Bottles Made Of?

Before the mass production techniques of the 20th century, perfume bottles were often precious, handcrafted objects made from a variety of materials, reflecting the artistry and technology of their time.

Old perfume bottles were made from a diverse range of materials. In ancient times, they were crafted from stone (alabaster), pottery, and hollowed-out gourds. Later, glass became prominent, with Victorian-era bottles often featuring cut glass or crystal with ornate sterling silver tops. Other materials included porcelain, enamel, and precious metals.

The materials used in antique bottles are a key factor in their collectibility and value.

Materials Through History:

- Ancient Egypt, Rome, Greece:

- Alabaster, Onyx: Carved stone vessels.

- Pottery & Faience: Glazed earthenware.

- Core-Formed Glass: An early and expensive form of glass making.

- 18th Century:

- Porcelain: Became very popular, often in figural shapes (people, animals) from factories like Meissen or Sèvres.

- Enamel on Metal: Small, intricately painted enamel bottles.

- Victorian Era (19th Century):

- Cut Glass & Crystal: Became more accessible. Bottles often featured intricate patterns and were paired with sterling silver caps and collars.

- Art Glass: Cameo glass (e.g., Thomas Webb & Sons), colored glass (Bristol blue), and opaline glass were popular.

- Double-Ended Bottles: Often glass with metal caps, one end for perfume, the other for smelling salts.

- Art Nouveau (c. 1890-1910):

- Silver Overlay on Glass: Intricate, flowing silver designs over glass bottles.

- Iridescent Glass: From makers like Loetz and Tiffany.

- Art Deco (c. 1920-1930s):

- Molded & Pressed Glass: Became dominant, allowing for more complex shapes.

- Bakelite: An early plastic, used for caps and sometimes entire bottles.

- Chrome: Used for metal accents.

The shift in the early 20th century, led by designers like René Lalique, moved perfume packaging from a craft of jewelers and glass artists into a more industrialized art form, making beautifully designed soda-lime glass bottles accessible to a wider audience and establishing it as the standard material we know today.

Conclusion

Modern perfume bottles are sophisticated assemblies, predominantly made of high-quality soda-lime glass to ensure the purity and stability of the fragrance. The complete package includes a complex plastic and metal atomizer, a plastic dip tube, and a cap crafted from a wide array of materials chosen for their aesthetic and tactile qualities. The common use of thick glass serves to enhance the bottle’s stability and convey a powerful sense of luxury and value. This evolution from ancient stone and porcelain to modern, precision-manufactured glass and metal components tells a rich story of art, chemistry, and commerce.