The global marketplace relies heavily on the movement of goods, and with those goods comes a vast array of packaging. Many countries import specific types of packaging materials or finished packaging solutions to meet domestic demand or for re-export.

A wide variety of packaging is imported globally, including primary packaging (e.g., specialized plastic bottles, glass vials, metal cans), secondary packaging (e.g., high-quality printed folding cartons, luxury rigid boxes), raw materials for packaging (e.g., plastic resins, paper pulp, aluminum foil), and packaging machinery.

The international trade in packaging is a complex web driven by factors like cost, specialization, material availability, and technological capabilities. As a global packaging manufacturer, ShineTop often exports finished custom packaging (like cosmetic boxes and containers) to brands all over the world, so we’re an active part of this import/export dynamic.

What are the 4 Types of Packaging?

Understanding the basic categories of packaging helps to clarify what kinds of packaging are typically involved in trade, whether domestic or international.

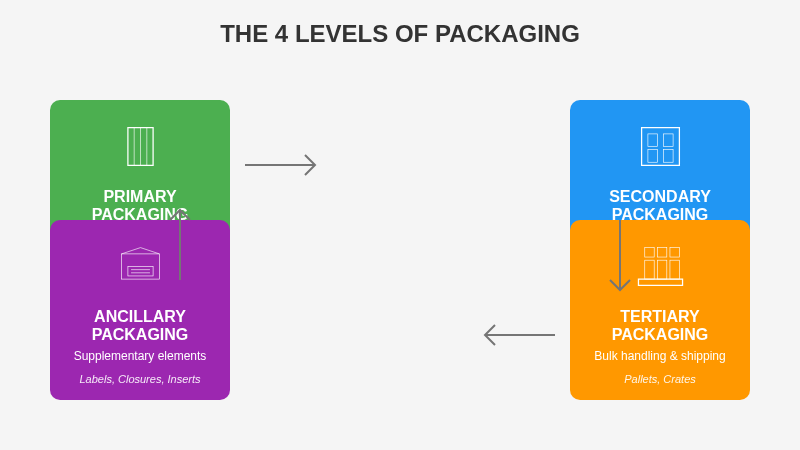

The four main types (or levels) of packaging are: 1. Primary Packaging (in direct contact with the product), 2. Secondary Packaging (groups primary packages, e.g., a retail box), 3. Tertiary Packaging (for bulk handling and shipping, e.g., a palletized load), and sometimes 4. Ancillary Packaging (items like labels, closures, inserts).

These levels describe the packaging’s relationship to the product and its role in the supply chain.

The Four Packaging Levels Explained:

-

Primary Packaging:

- Definition: The material that first envelops the product and holds it. It is in direct contact with the product.

- Purpose: Containment, protection of the product from contamination, dispensing, and often, initial branding.

- Examples: A soda can, a candy wrapper, a medicine bottle, a cosmetic jar, a vacuum-sealed pouch for food.

- Import/Export: Specialized primary packaging (e.g., unique bottle shapes, high-barrier films, specific dispensing systems) is often imported if local manufacturing capabilities are limited or more expensive.

-

Secondary Packaging:

- Definition: The packaging outside the primary packaging, used to group primary packages together or to provide additional branding, information, and protection.

- Purpose: Retail display, branding, product information, protection of primary packs.

- Examples: A cardboard box holding multiple soda cans (a "fridge pack"), the retail box for a cosmetic jar, a shrink-wrapped tray of water bottles.

- Import/Export: High-quality printed folding cartons, luxury rigid boxes, or custom display packaging are frequently imported by brands seeking specific aesthetics or cost advantages. ShineTop specializes in exporting these.

-

Tertiary Packaging (Transit/Transport Packaging):

- Definition: Packaging used for bulk handling, warehouse storage, and shipping. It groups secondary packages (or sometimes many primary packages) for efficient and safe transit.

- Purpose: Protection during shipping, ease of handling (e.g., with forklifts), unitization.

- Examples: Corrugated shipping cartons (master cartons), stretch-wrapped pallets, wooden crates, large shipping containers.

- Import/Export: While basic corrugated boxes are often sourced locally, specialized transit packaging or components might be imported. The products within tertiary packaging are, of course, the primary subject of import/export.

-

Ancillary Packaging (Sometimes considered part of other levels):

- Definition: Materials used to support or complement the main packaging components.

- Purpose: Sealing, labeling, cushioning, providing instructions, enhancing presentation.

- Examples: Labels, adhesives, closures (caps, pumps, lids), inserts, cushioning materials (bubble wrap, foam), instruction leaflets, ribbons.

- Import/Export: Specific types of closures (e.g., high-performance pumps, unique caps), specialized labels, or custom inserts are often imported.

All these types of packaging can be subject to international trade.

What Type of Packaging is Used for Export?

When goods are shipped internationally, the packaging must be robust enough to withstand the rigors of a long and often complex journey, while also meeting any specific import/export regulations.

For export, tertiary packaging (transit packaging) is paramount. This typically includes sturdy corrugated cardboard boxes (often double or triple-walled), wooden crates or pallets (often requiring ISPM 15 heat treatment), stretch wrap, strapping, and cushioning materials. The primary and secondary packaging within must also be durable enough for the journey and meet the destination market’s standards.

Export packaging prioritizes protection, security, and compliance.

Key Characteristics & Types of Export Packaging:

-

Durability & Strength:

- Must withstand multiple handlings, stacking pressures, vibrations, temperature fluctuations, and potential impacts during sea, air, or land transport.

- Materials: Heavy-duty corrugated cardboard, wooden crates, plastic or metal drums/containers for certain goods.

-

Protection from Environmental Factors:

- Moisture: Use of desiccants, vapor barrier liners, or waterproof wraps may be necessary, especially for sea freight.

- Temperature: Insulated packaging for temperature-sensitive goods.

- Pests: Wooden packaging materials (pallets, crates) usually require ISPM 15 international standard treatment (heat treatment or fumigation) to prevent the spread of pests.

-

Security:

- Tamper-evident seals, strong strapping, and secure closures to prevent theft or unauthorized access.

-

Efficient Handling & Unitization:

- Palletization: Goods are often stacked on pallets (wooden, plastic, or metal) and secured with stretch wrap or strapping for easy handling by forklifts.

- Containerization: Goods are packed into standard shipping containers for sea or land freight.

-

Compliance & Labeling:

- Markings: Clear markings for destination, handling instructions (e.g., "Fragile," "This Way Up," international symbols), country of origin, weight, and any hazardous material warnings.

- Documentation: Packaging must allow for easy access to shipping documents if needed.

- Import Regulations: Must comply with the packaging regulations of the importing country (e.g., restrictions on certain materials, labeling requirements).

-

Cost-Effectiveness & Space Optimization:

- Packaging should be designed to maximize space utilization within shipping containers or aircraft to minimize transport costs, while still providing adequate protection.

The primary and secondary packaging inside the export packaging also needs to be robust. For example, if ShineTop exports luxury cosmetic boxes to a client in Europe, those boxes (secondary packaging) are carefully packed into strong master cartons (tertiary packaging) and palletized for their journey.

What Type of Packaging is Most Widely Used?

Globally, across all industries, certain types of packaging materials see the highest volume of use due to their versatility, cost-effectiveness, and suitability for a vast range of products.

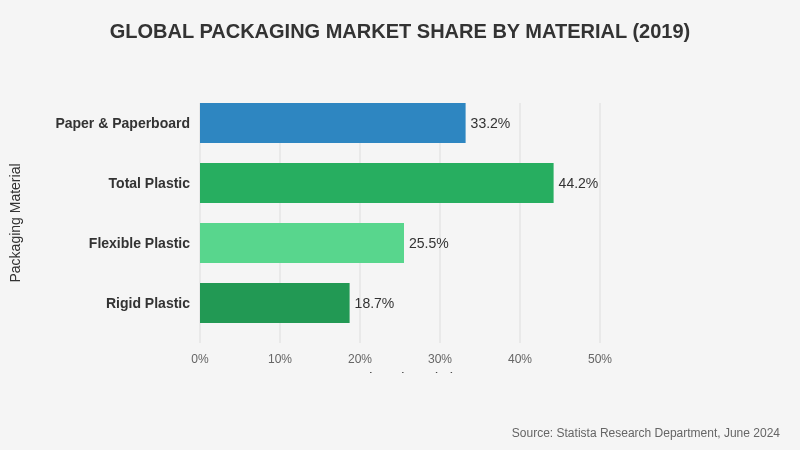

Plastics and paper/paperboard (including corrugated cardboard) are generally the most widely used types of packaging materials globally by volume. Plastics are favored for their versatility and light weight in primary packaging, while paper/paperboard dominates secondary and tertiary (shipping) packaging due to its cost-effectiveness and printability.

The widespread use of these materials is driven by their balance of performance, cost, and adaptability.

Dominant Packaging Material Types:

-

Plastics:

- Why: Lightweight, strong, shatter-resistant, excellent versatility in form (bottles, films, trays, tubs, closures), good barrier properties (can be tailored), relatively low cost.

- Examples: PET bottles for beverages, HDPE containers for household chemicals, PP tubs for food, flexible films for food packaging, LDPE shrink wrap.

- Concerns: Environmental impact of fossil fuel derivation and plastic waste, leading to a push for more recycled content (PCR) and recyclable designs.

-

Paper & Paperboard (including Corrugated):

- Why: Cost-effective, lightweight, excellent printability for branding, good structural properties (especially corrugated for shipping), renewable resource (if sourced sustainably), widely recyclable.

- Examples: Corrugated boxes for e-commerce and shipping (ubiquitous), folding cartons for food/cosmetics/pharmaceuticals, paper bags, labels, liquid packaging board (drink cartons).

- Growth Driver: E-commerce has significantly boosted demand for corrugated packaging.

While plastics and paper/paperboard lead in overall volume, metal (aluminum and steel for cans) and glass (for beverages, food, pharmaceuticals, cosmetics) are also very significant and are often preferred for their specific properties like superior barrier (metal, glass) or inertness and premium feel (glass).

The "most widely used" can also depend on the specific industry segment. For instance, in the beverage can industry, aluminum is dominant. For shipping boxes, corrugated paperboard is king.

What is Packaging in International Trade?

In the context of international trade, packaging takes on an even more critical and complex role than in domestic commerce. It’s not just about containing and protecting a product; it’s about navigating global supply chains and regulations.

In international trade, packaging refers to the materials and methods used to protect goods during their journey across borders, facilitate their handling and storage through diverse logistical systems, comply with varying international regulations and standards (e.g., ISPM 15 for wood, labeling requirements), and ensure they arrive at the international destination in a safe, saleable, and legally compliant condition.

Packaging in international trade is a specialized discipline that addresses the unique challenges of moving goods globally.

Key Aspects of Packaging in International Trade:

-

Enhanced Protection:

- Goods face greater risks over longer distances and multiple handling points (ports, customs, various transport modes). Packaging must be exceptionally robust.

-

Compliance with International Standards & Regulations:

- ISPM 15: For wood packaging materials (pallets, crates) to prevent pest spread.

- Labeling Requirements: Country of origin, language requirements, specific warning labels, net weight in metric/imperial as needed.

- Material Restrictions: Some countries restrict or tax certain packaging materials.

- Dangerous Goods Regulations: Specific packaging and labeling for hazardous materials (IATA for air, IMDG for sea).

-

Customs & Biosecurity:

- Packaging must allow for inspection by customs officials if required.

- Materials must not pose a biosecurity risk.

-

Logistical Efficiency:

- Standardized sizes (e.g., pallet dimensions that fit well in containers) are crucial for optimizing shipping space and cost.

- Ease of handling by different types of equipment in various countries.

-

Cost Optimization:

- Balancing the need for protection with the cost of materials and the impact of packaging weight/volume on freight charges.

-

Cultural & Market Adaptation:

- Sometimes, secondary or even primary packaging might need to be adapted (e.g., language, imagery) for the target export market, though this is more about the product’s retail presentation than the transit packaging itself.

-

Sustainability Considerations:

- Growing pressure to use more sustainable packaging in international trade to reduce global waste and carbon footprint.

Anna, a cosmetics manufacturer in Thailand, exports some of her products. When she does, the primary and secondary packaging we at ShineTop provide must be durable. Then, her freight forwarder ensures the tertiary (export) packaging meets all the requirements for her destination markets, including proper palletizing and documentation. This ensures her beautifully packaged cosmetics arrive safely and can be legally sold.

Conclusion

A vast array of packaging types and materials are imported and exported globally, driven by specialization, cost, and demand. From primary containers to robust tertiary packaging for export, each level serves critical functions. While plastics and paper/paperboard are the most widely used materials overall, the specific needs of international trade demand packaging that is exceptionally protective, compliant with diverse regulations, and logistically efficient to ensure goods traverse the globe safely and successfully.