Walk down any beauty aisle, and you’re greeted by a dazzling array of cosmetic packaging, each material chosen for its specific properties, aesthetic appeal, and ability to protect the precious formula within. Understanding these common materials is key for any brand.

Commonly used materials for cosmetic packaging include plastics (like PET, PP, PE, HDPE, LDPE, Acrylic/PMMA, SAN), glass, paper and paperboard (for boxes and labels), and metals (primarily aluminum and tinplate). The choice depends on product compatibility, desired aesthetics, cost, functionality, and sustainability goals.

The selection of packaging material is a critical decision in cosmetic product development, influencing everything from shelf life to brand perception. As a global packaging manufacturer with ShineTop for over two decades, we work extensively with all these materials, tailoring them to our clients’ unique needs. Let’s explore the main players.

What Material is Used for Cosmetic Packaging?

While a variety of materials are employed, a few stand out due to their versatility, cost-effectiveness, and suitability for the diverse range of cosmetic products on the market.

Plastic is the most widely used material for primary cosmetic packaging (bottles, jars, tubes) due to its versatility, light weight, and cost-effectiveness. Glass is favored for luxury and fragrance products. Paper/paperboard is dominant for secondary packaging (boxes). Aluminum is common for tubes and aerosol cans.

Each material brings a unique set of advantages to the table, making it suitable for different types of cosmetic products and brand positionings.

Primary Material Categories in Cosmetic Packaging:

-

Plastics:

- Why Common: Lightweight, shatter-resistant, highly versatile in shape and form, can be transparent or opaque, relatively inexpensive to produce, good barrier properties (varies by type).

- Specific Types:

- PET (Polyethylene Terephthalate): Excellent clarity, good barrier to oxygen and moisture. Common for bottles (lotions, cleansers, micellar water).

- PP (Polypropylene): Good chemical resistance, higher heat tolerance, often used for jars, caps, airless components. Can be clear or opaque.

- PE (Polyethylene – HDPE/LDPE): HDPE (High-Density) is rigid (shampoo bottles, milkier appearance). LDPE (Low-Density) is flexible and squeezable (tubes, some bottles).

- PMMA (Acrylic) & SAN (Styrene Acrylonitrile): Offer glass-like clarity and a more premium feel than basic plastics. Used for luxury jars and thick-walled bottles.

- ShineTop Expertise: We offer a vast range of plastic packaging, including PCR (Post-Consumer Recycled) options in PET, PE, and PP.

-

Glass:

- Why Common: Premium look and feel, chemically inert (doesn’t react with product), excellent barrier against gases and moisture, impermeable to odors, highly recyclable.

- Uses: Luxury skincare (serums, creams), foundations, perfumes, nail polish. Amber or cobalt blue glass for light-sensitive formulas.

- ShineTop Expertise: We are a major manufacturer of cosmetic glass bottles and jars, with extensive post-processing capabilities (frosting, coating, printing).

-

Paper & Paperboard:

- Why Common (Primarily for Secondary Packaging): Excellent printability for branding, versatile for structural design (boxes), lightweight, renewable (if sourced sustainably), widely recyclable.

- Types: SBS (Solid Bleached Sulfate) for a clean, white print surface; CUK/CNK (Coated Kraft) for strength; recycled board for eco-options; Kraft for a natural look.

- Uses: Outer boxes for almost all cosmetic products, labels, inserts, gift sets.

- ShineTop Expertise: Our self-owned factories produce a huge volume of custom cosmetic boxes with various finishes.

-

Metals (Mainly Aluminum):

- Why Common: Excellent barrier properties (light, air, moisture), lightweight (aluminum), durable, distinctive aesthetic, highly recyclable.

- Uses: Collapsible tubes (creams, ointments, hair dyes), aerosol cans (hairsprays, dry shampoos), tins (lip balms, solid perfumes), caps, decorative components on bottles/jars.

- ShineTop Expertise: We produce aluminum components and can apply various surface treatments.

The choice often involves balancing the product’s needs (e.g., an oxygen-sensitive serum might need an airless plastic pump or a well-sealed glass bottle with an outer box) with the brand’s image (e.g., luxury brands often lean towards glass and premium finishes on paperboard boxes).

What Material is Commonly Used for Packaging?

Looking beyond just cosmetics, certain materials dominate the general packaging landscape due to their broad applicability, cost-effectiveness, and established manufacturing infrastructure.

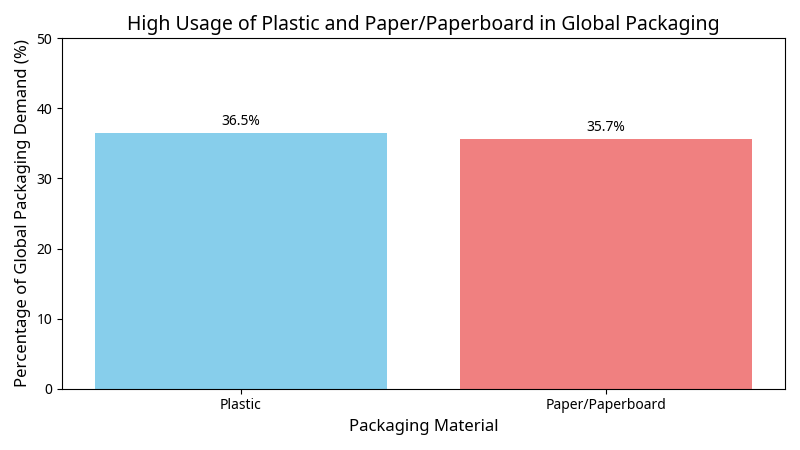

Plastics and paper/paperboard (including corrugated cardboard) are the most commonly used materials for packaging globally by volume. Plastics offer versatility for primary packaging across many industries, while paper/paperboard is essential for secondary and tertiary (shipping) packaging.

These two material groups are ubiquitous in our daily lives, packaging everything from food and beverages to electronics and, of course, cosmetics.

Why Plastics and Paper/Paperboard Dominate:

-

Plastics:

- Versatility: Can be rigid or flexible, clear or opaque, molded into infinite shapes.

- Lightweight: Reduces shipping costs and energy consumption during transport.

- Cost-Effectiveness: Generally economical to produce in large volumes.

- Durability: Shatter-resistant and can offer good product protection.

- Barrier Properties: Can be engineered for specific needs (e.g., oxygen, moisture).

- Common Examples: PET bottles, HDPE jugs, PP containers, LDPE films, PS trays.

-

Paper & Paperboard:

- Cost-Effectiveness: Particularly for boxes and shipping materials.

- Printability: Provides an excellent surface for branding, graphics, and information.

- Lightweight: Contributes to lower shipping costs.

- Renewable Resource: If sourced from sustainably managed forests (e.g., FSC-certified).

- Recyclability: Widely recycled in most regions (if not heavily contaminated or laminated with non-recyclable plastics).

- Structural Strength: Corrugated paperboard is exceptionally strong for its weight, ideal for shipping boxes.

- Common Examples: Cereal boxes, e-commerce shipping boxes, food cartons, cosmetic boxes, labels.

While metal (for cans) and glass (for bottles and jars) are also very common and essential for specific product categories (e.g., beverages, preserved foods, pharmaceuticals, luxury items), plastics and paper/paperboard tend to have the highest overall consumption by volume in the global packaging market.

What is the Best Plastic for Cosmetic Packaging?

With so many types of plastics available, brands often wonder which one is "best" for their specific cosmetic packaging needs. The answer depends on the product, desired aesthetics, and functional requirements.

There isn’t one single "best" plastic for all cosmetic packaging. PET is excellent for clarity and good barrier in bottles. PP is valued for its chemical resistance and heat tolerance in jars and caps. HDPE offers robust, cost-effective bottles. LDPE is ideal for squeezable tubes. Increasingly, PCR (Post-Consumer Recycled) versions of these plastics are considered "best" from a sustainability standpoint.

The "best" plastic is the one that best meets the specific needs of the cosmetic product and brand.

Popular Plastics for Cosmetics & Their Strengths:

-

PET / PETE (Polyethylene Terephthalate – #1):

- Pros: Excellent clarity (glass-like), good barrier to oxygen and moisture, good strength, lightweight, highly recyclable.

- Best For: Bottles for lotions, serums, toners, micellar waters, some jars.

- Eco-Note: Widely available in PCR grades.

-

PP (Polypropylene – #5):

- Pros: Good chemical resistance, good moisture barrier, higher melting point (can withstand warmer temperatures), good fatigue resistance (for hinged caps), can be made clear (clarified PP) or opaque.

- Best For: Jars for creams and balms, caps and closures, airless pump components, some bottles.

- Eco-Note: Recyclable (check local facilities); PCR PP is becoming more common.

-

HDPE (High-Density Polyethylene – #2):

- Pros: Good moisture barrier, good impact resistance, more rigid than LDPE, cost-effective. Often naturally translucent/milky but can be colored.

- Best For: Bottles for shampoos, conditioners, body washes, some cleansers.

- Eco-Note: Widely recycled; PCR HDPE is available.

-

LDPE (Low-Density Polyethylene – #4):

- Pros: Very flexible and squeezable, good moisture barrier, tough.

- Best For: Squeezable tubes for creams, lotions, gels, cleansers. Some flexible bottles.

- Eco-Note: Recyclable (often in specific streams like film recycling, though rigid LDPE can be curbside); PCR LDPE exists.

-

PMMA (Polymethyl Methacrylate – Acrylic – #7):

- Pros: Excellent clarity and gloss (very glass-like), premium feel, good scratch resistance.

- Cons: More expensive, more brittle than other plastics, harder to recycle.

- Best For: Luxury jars, thick-walled bottles, high-end compacts.

-

SAN (Styrene Acrylonitrile) / AS (Acrylonitrile Styrene – #7):

- Pros: Good clarity, stiffness, good chemical resistance to some products.

- Cons: Can be brittle, #7 plastic recycling is limited.

- Best For: Clear jars (often double-walled with PP inner), caps, some compacts.

When Anna, a cosmetics client of ShineTop in Thailand, was choosing plastic for her natural cleansers, she opted for PCR PET bottles to align with her brand’s sustainability focus while still getting excellent clarity to showcase the product. For her richer creams, she uses PP jars.

What is the Primary Packaging of Cosmetics?

Understanding the distinction between primary and other levels of packaging is fundamental in the cosmetics industry. Primary packaging is the unsung hero that directly interacts with and protects your formula.

The primary packaging of cosmetics is the container or packaging component that is in direct physical contact with the cosmetic product itself. Its main functions are to contain the product, protect it from contamination and degradation, ensure compatibility with the formulation, and facilitate its dispensing or application.

Primary packaging is the first line of defense for your cosmetic product and the immediate interface for the consumer.

Examples of Primary Packaging in Cosmetics:

- The bottle that holds a lotion, serum, or foundation.

- The jar that contains a face cream, body butter, or eye cream.

- The tube (plastic, laminate, or aluminum) that dispenses a gel, cream, or cleanser.

- The lipstick mechanism (bullet, base, cap) that houses the lipstick.

- The mascara vial and wand assembly.

- The compact (including the pan/godet) that holds pressed powder, blush, or eyeshadow.

- The airless pump bottle or jar directly containing and dispensing a sensitive formula.

- The dropper assembly (pipette and bulb) within a serum bottle.

- An ampoule containing a single dose of a concentrate.

- A sachet holding a single-use face mask or product sample.

Key Considerations for Primary Packaging:

- Material Compatibility: Must be inert and not react with the cosmetic ingredients (e.g., certain plastics might not be suitable for high-alcohol or essential oil content).

- Barrier Properties: Needs to protect the formula from oxygen, light, moisture, or other factors that could cause it to degrade, lose efficacy, or change color/odor.

- Safety & Non-Toxicity: Materials must be safe for contact with products applied to the skin.

- Functionality: Must allow for easy and appropriate dispensing of the product.

- Aesthetics: While often covered by secondary packaging, the primary pack still contributes to the overall brand experience, especially for products displayed without a box or during use.

At ShineTop, a significant portion of our manufacturing focuses on primary packaging components – producing high-quality glass bottles and jars, a wide array of plastic containers and tubes, and various closures and dispensers, all designed to meet the exacting standards of the cosmetics industry.

Conclusion

The materials commonly used for cosmetic packaging – primarily plastics, glass, paper/paperboard, and metals like aluminum – are chosen for their unique ability to protect diverse formulations, convey brand aesthetics, and meet functional needs. While plastics like PET, PP, and PE are versatile workhorses, especially for primary containers, and paperboard is key for secondary boxes, the "best" material always depends on the specific product, brand goals, and a growing emphasis on sustainability. Understanding these materials is the first step to creating packaging that truly shines.